Pourquoi des tenues de trail éco-responsables ?

On estime qu’en 100 ans, la planète s’est réchauffée de 0,9°C[1]. Les conséquences de ce réchauffement, notre génération en est déjà témoin : disparition de la banquise en été, fonte accélérée de nos glaciers, canicules et feux de forêt à répétition, acidification des océans, biodiversité gravement menacée[2]… Alors quand on m’explique que si on ne change rien à nos habitudes, il est possible que sur les 80 prochaines années la planète se réchauffe de 6,4°C supplémentaires, je ne sais pas vous, mais moi ça ne me laisse pas indifférent !

Quelle est l’empreinte carbone de l’industrie textile ?

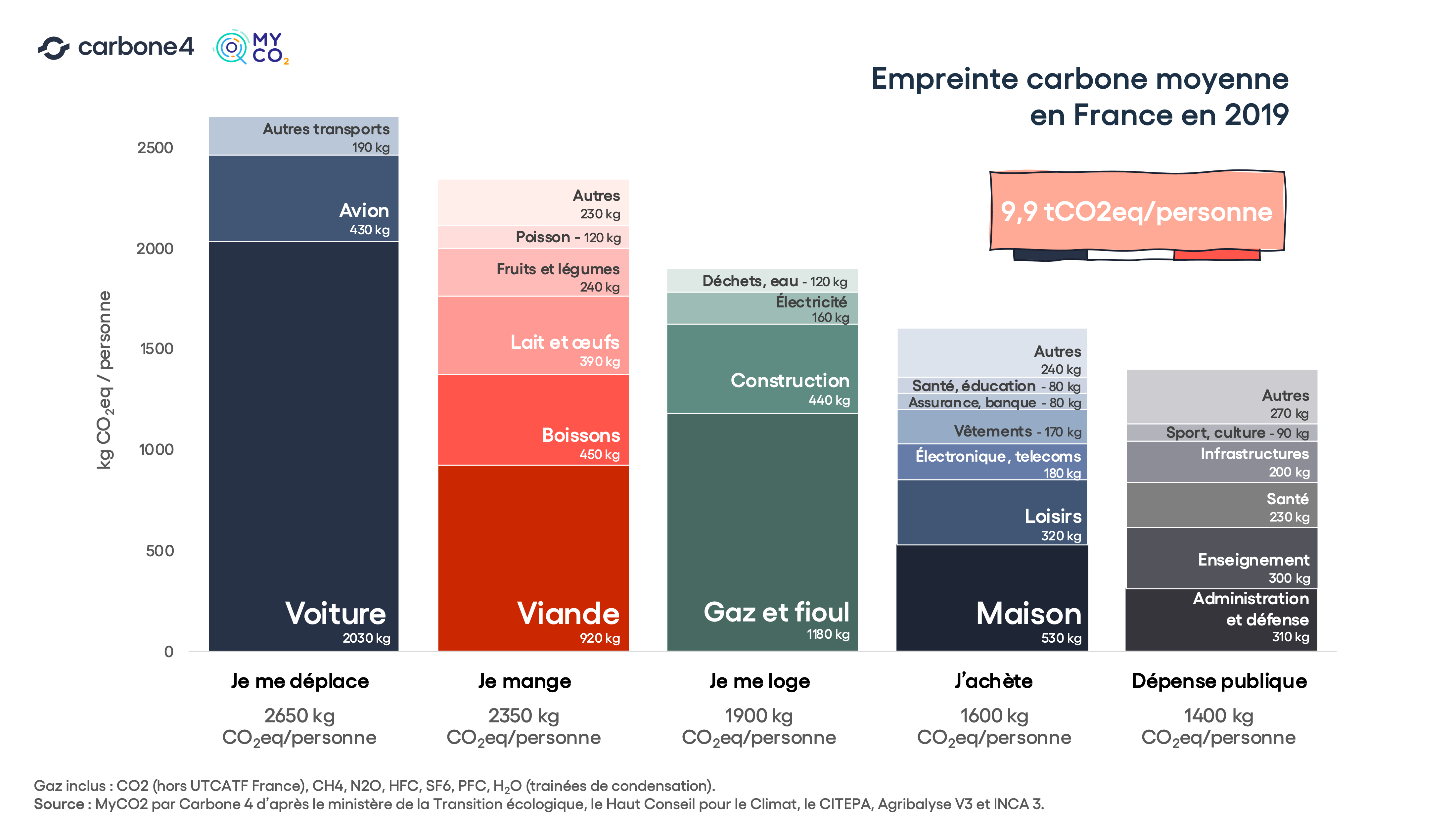

Lorsque l'on fait le bilan carbone d’un Français[4], on constate que les plus grosses sources d’émission sont l’alimentation (19,5%), le logement (19,2%) et l’utilisation de la voiture (16,3%). L’habillement arrive un peu plus loin derrière avec 6,3% des émissions. Ainsi, à l’échelle nationale, l’habillement émet davantage que l’industrie aéroportuaire ou la consommation des biens électroménagers.

Bien évidemment, si vous cherchez à réduire votre empreinte carbone, une première étape consisterait par exemple à consommer davantage de produits locaux, isoler votre appartement et vous déplacer plus souvent à vélo ! Cependant, même en appliquant ces changements à l’extrême, navré de vous l’annoncer mais on serait loin du compte !

En effet, avec 9,9 tonnes d’émission de CO2 par an, le Français est encore très loin de faire ce qu’il faudrait pour atteindre ne serait-ce que le seuil de 2°C de réchauffement supplémentaire par rapport aux niveaux préindustriels (seuil défini lors des accords de Paris[5]).

Pour respecter cet engagement, il y a plus ou moins consensus sur le fait que nos émissions ne devraient pas dépasser 2 tonnes de CO2 par an et par habitant[6] : Un sacré régime !

Avec 170kg de CO2 par an, l’habillement consommerait donc 10% de notre budget carbone, et c'est donc tout l'enjeu de faire des vêtements à faible impact environnemental.

Made In où-ça ?

Quand on parle d'écoresponsabilité dans le textile, nous sommes frappés par le fait que tout le débat se concentre sur le lieu de confection.

Il est évident que celui-ci va refléter les conditions de travail et traite du volet "responsable" de notre problématique.

Mais passé le fait qu'il est à notre sens normal de produire dans des conditions de travail "normales" (c'est ce qu'un Made in UE garantit), ce n'est pas vraiment là que se concentrent les enjeux environnementaux.

En effet, la partie confection représente au plus 10% des émissions de CO2eq, et les transports (s'ils ne sont pas faits par avion, ce qui est rare), représenteront eux aussi guère plus de 10%-12% eux aussi.

Hé oui, d'un point de vue émissions de CO2eq, et pollution au sens large, c'est la matière qui concentre toutes les problématiques environnementales.

Du naturel s'il vous plait ! Vraiment ??

C'est généralement la première question qu'on nous pose : "est-ce que vos vêtements sont en fibres naturelles ?"

Résumer le débat à cette question est malheureusement beaucoup trop simpliste.

La fabrication du coton, par exemple, n'utilise certes pas d'hydrocarbure comme matière première. Mais, sa culture nécessite des tracteurs ; son traitement des machines ; la fabrication des fils aussi... bref, ce processus industriel est à l'origine d'émissions de CO2eq.

Pour savoir ce qu'il en est et comparer des procédés industriels entre eux, on réalise ce qu'on appelle une Analyse de Cycle de Vie (ACV, ou LCA en anglais).

L'ACV comme juge de paix

Certaines ACV disponible sur le net montrent qu'un coton économise environ 41% d’énergie en moins qu'un polyester vierge. Cependant, il relâche paradoxalement 39% de CO2eq en plus dans l'atmosphère (émissions non captées).

A cela s'ajoute le fait qu'il faudra 22 000 Litres d’eau pour obtenir 1 kg de coton contre 17 Litres pour obtenir autant de polyester[8]! Différence notable quand on sait que l’intensification de la production du coton en Ouzbékistan et au Kazakhstan depuis les années 60 est directement responsable de l’assèchement de la mer d’Aral[9].

Ces considérations doivent finalement être mises en perspectives de la durabilité et ici, l'équation penche nettement en faveur du Polyester. Car à densité de tissu équivalente le Polyester aura une resistance 2 à 10 fois supérieure au coton, ce qui permet de ramener l'empreinte carbone par utilisation à un niveau bien plus bas que ce qu'obtiendrait une fibre naturelle, notamment si le tissu risque d'être soumis a de fortes contraintes comme c'est le cas dans le trail...

Et le recyclé alors ?

Le débat est à peu près de même nature, et la première idée reçue qui mérite d'être tuée c'est que tout ce qu'on met au bac de recyclage n'est pas forcément recyclable, bien au contraire !

En réalité, seul une infime partie des déchets plastique que l'on y met le sont. Il s'agit généralement des plastiques numéroté 1 (PET), 2 (PEHD) et 5 (PP), numéro que l'on peut retrouver au dos des emballages. Faites l'exercice de regarder derrière vos pots de yaourts et autre recipients et vous serez surpris de voir ce qui mérite réellement de finir au bac de recyclage !

Le plastique communément recyclé dans l'industrie textile est le Polyester (PET). Il est obtenu par un procédé mécanique (il existe des procédés chimiques) à partir de bouteilles plastiques transparentes (la plupart du temps, les bouteilles de couleur ne rentrent pas dans ce processus pour des raisons de teinture (cela fait des taches sur les fils).

Si l'utilisation d'une matière première recyclée permet d'économiser de l'hydrocarbure, le processus de collecte ainsi que les différents traitements mécaniques viennent finalement alourdir le bilan carbone de ces fibres recyclées.

Là aussi, une ACV réalisée sur un fil Newlife fabriqué en Italie (probablement la référence européenne en terme de fil en PET recyclé) révèle 32% d'économie de CO2 par rapport à un PET vierge fabriqué au même endroit : ce n'est pas énorme, car ajouté à cela les étapes communes de texturation, de moulinage, d'ourdissage et de tissage, l'économie finale n'est plus que de 10 à 15% de CO2eq par rapport à un tissu fait avec un PET vierge.

Le mix énergétique avant tout !

A nos yeux, des considérations sur le lieu de fabrication de la matière et le mix énergétique utilisé sont bien plus impactantes !

En s'appuyant ainsi sur les chiffres de l'IEA, on s'aperçoit que les émissions de CO2eq par énergie produite sont 71% plus élevées en Italie qu'en France (5ème mix énergétique le plus bas carbone au monde).

Conclusion : mieux vaut choisir un bon tissu français en PET vierge qu'un tissu recyclé italien, espagnol ou portugais !

D'autres facteurs de pollution

A cette pollution par le carbone s’ajoutent d’autres pollutions. La teinte et l’ennoblissement des fibres textiles a notamment recours à une très importante quantité de produits chimiques. Or tous les pays ne sont pas égaux face au traitement de ces déchets, et bien sûr, les moins consciencieux sont aussi les principaux producteurs[7]!

Bref, l’industrie Textile, ce n'est pas toujours joli si on ne fait pas gaffe où on mets les pieds ! Et c'est surtout facile de s'y perdre dès qu'il s'agit d'acheter responsable. On vous invite pour cela à jeter un coup d’œil à la boutique SloWeAre, une plateforme qui recense des marques engagées et éthiques et qui vous aidera à vous faire une garde robe "propre".

[1]https://fr.wikipedia.org/wiki/R%C3%A9chauffement_climatique#cite_note-18

[2]https://www.ecologique-solidaire.gouv.fr/observatoire-national-sur-effets-du-rechauffement-climatique-onerc#e2

[3]https://jancovici.com/changement-climatique/gaz-a-effet-de-serre-et-cycle-du-carbone/quels-sont-les-gaz-a-effet-de-serre-quels-sont-leurs-contribution-a-leffet-de-serre/

[5]https://fr.wikipedia.org/wiki/Accord_de_Paris_sur_le_climat

[6]https://www.lemonde.fr/planete/article/2019/04/11/combien-de-co2-pourrez-vous-emettre-dans-votre-vie-si-le-rechauffement-est-contenu-a-1-5-degre_5448606_3244.html

[7]A New Textile Economy : https://www.ellenmacarthurfoundation.org/publications/a-new-textiles-economy-redesigning-fashions-future

[8]https://pdfs.semanticscholar.org/80e3/da631dd6d7d86d288275c390e63849fc4498.pdf

[9]https://fr.wikipedia.org/wiki/Mer_d%27Aral

[10]https://www.amfori.org/resource/countries-risk-classification ;

[11]https://www.francetvinfo.fr/replay-magazine/france-2/cash-investigation/cash-investigation-du-mardi-28-novembre-2017_2478912.html

Laissez un commentaire